| ETA-hyväksyntä | |

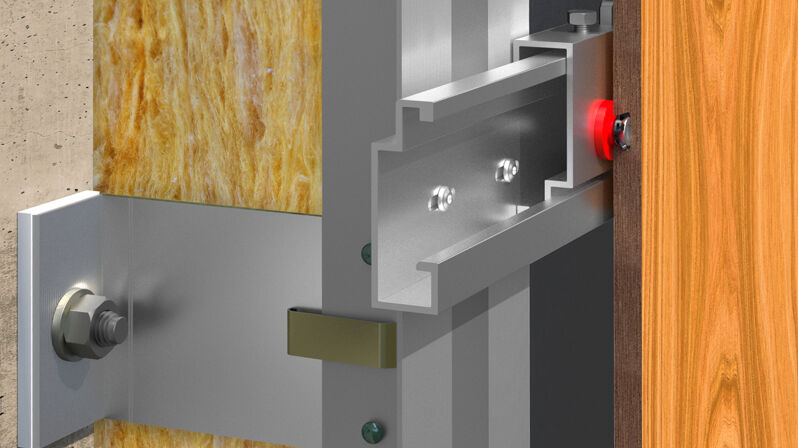

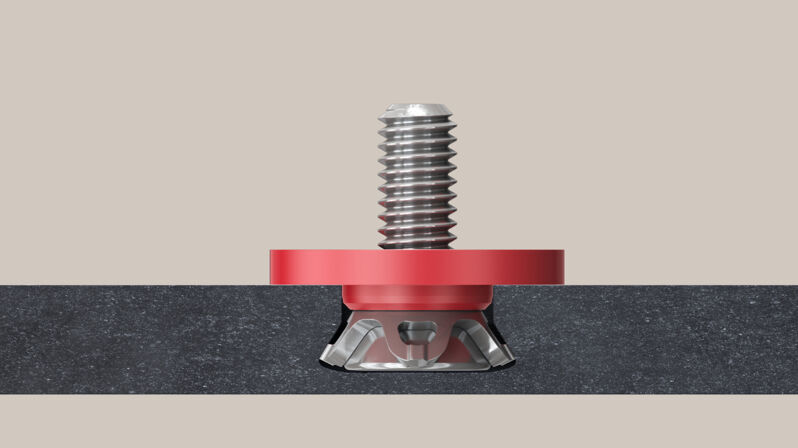

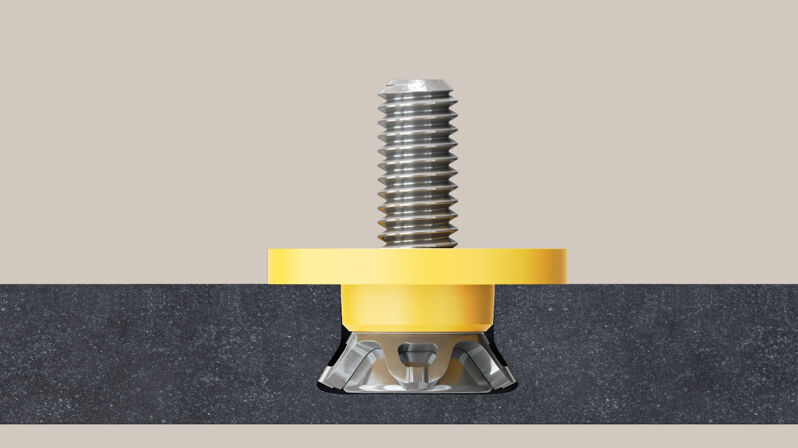

| Levyn min. paksuus | 10 mm |

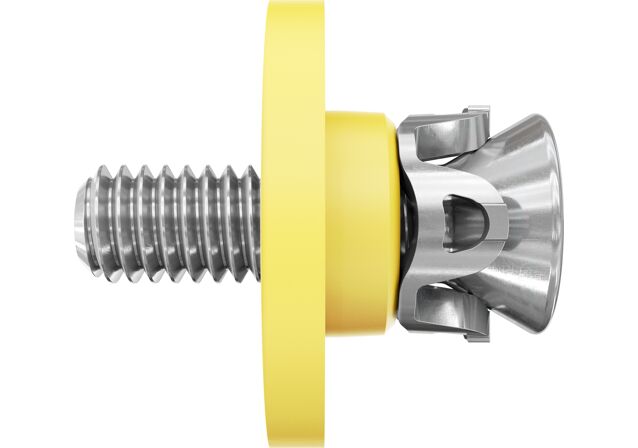

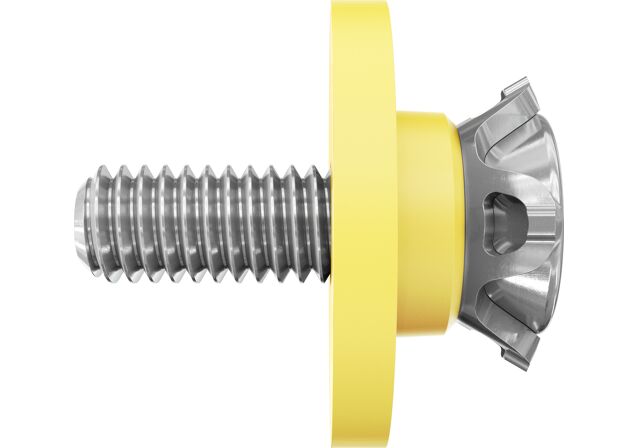

| Kiinnityssyvyys | 8 mm |

| Kokonaispituus ( l ) | 22,5 mm |

| Asennetun ankkurin pituus | 10,5 mm |

| Jäljellä oleva kierteen pituus | 12 mm |

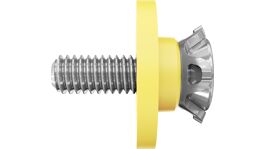

| Kierre ( M ) | M6 |

| Sylinterimäinen halkaisija | 11 mm |

| Alileikkaushalkaisija | 13,5 mm |

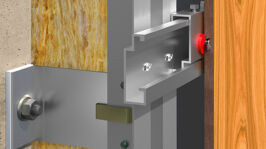

| Hyväksyntä maanjäristysalueille | C1 / C2 |

| Järjestelmä | — |

| Määrä | 250 Pa. |

| GTIN (EAN-Code) | 4048962168495 |